-

Post-race analysis

So, after crunching some numbers, the conclusion is, we added 1.48mph to our 1/8th record (now 110.08mph) so a new personal best there and came tantalisingly close to a new PB’s with the 60ft time being just 0.021s shy and the ET being 0.137s over. All in all, these are good results because we managed consistently close times which is something that has been missing in the last couple of seasons. I feel that once the nitrous is dialled in properly, we will beat these times and head into a new level of competition capability.

-

Westonzoyland May 21

Friday 30th April We made it to Westonzoyland this afternoon. Set up camp, got most of the new track set up done and then this … The rain has passed leaving a dramatic sky in its wake. Saturday 1st May So here we are at WZ, signing on and tech inspection completed with the sun shining and just waiting for the riders meeting to happen so we can start racing and it’s raining…with the sun shining… so now we are going to have to wait an hour for the track to dry out. And so the sun shone and they did battle. Five runs in which were good. Not a…

-

Smeatharpe April 21

Friday 23rd April We are at Smeatharpe (Dakota Raceway) as the sun sets on a beautiful day. Tomorrow will see us finally testing all the engine work done over the last few weeks. Weather forecast is good and hopefully there will be good times and good times. Saturday 24th April The expression on my face today when I did the first, full throttle timed run. And that’s WITHOUT the nitrous… Today was a good day! It started last night (Friday) when I arrived at Dakota Raceway (Smeatharpe) and set up camp. I was invited to eat with some of the other riders who were indulging in a BBQ and after…

-

Cap head bolts

I fixed the oil leak today. While I was at it, I swapped out the pathetic little cap head bolts from the oil line brackets for M5 items. At least now I can A, see the damn things, B, find a tool to fit them. This is invaluable when accessing the depths of the bikes underside to put the brackets back on. #onlytaken3yearstosortitout

-

Are you sitting comfortably?

…This could take a while. The last couple of days have been something of a nightmare. We finally have a rebuilt motor and Saturday saw me putting it back in the frame for final fitting. Except that when I tried to fit the radiator bracket which is mounted on an engine mounting bolt, I hadn’t realised that the bolt was too short (it had torqued up ok on the previous motor) and stripped the threads in the cylinder head. Having been at it all day, I decided to leave it until Sunday so I could look at it with a fresh mind. The only option was a helicoil which I…

-

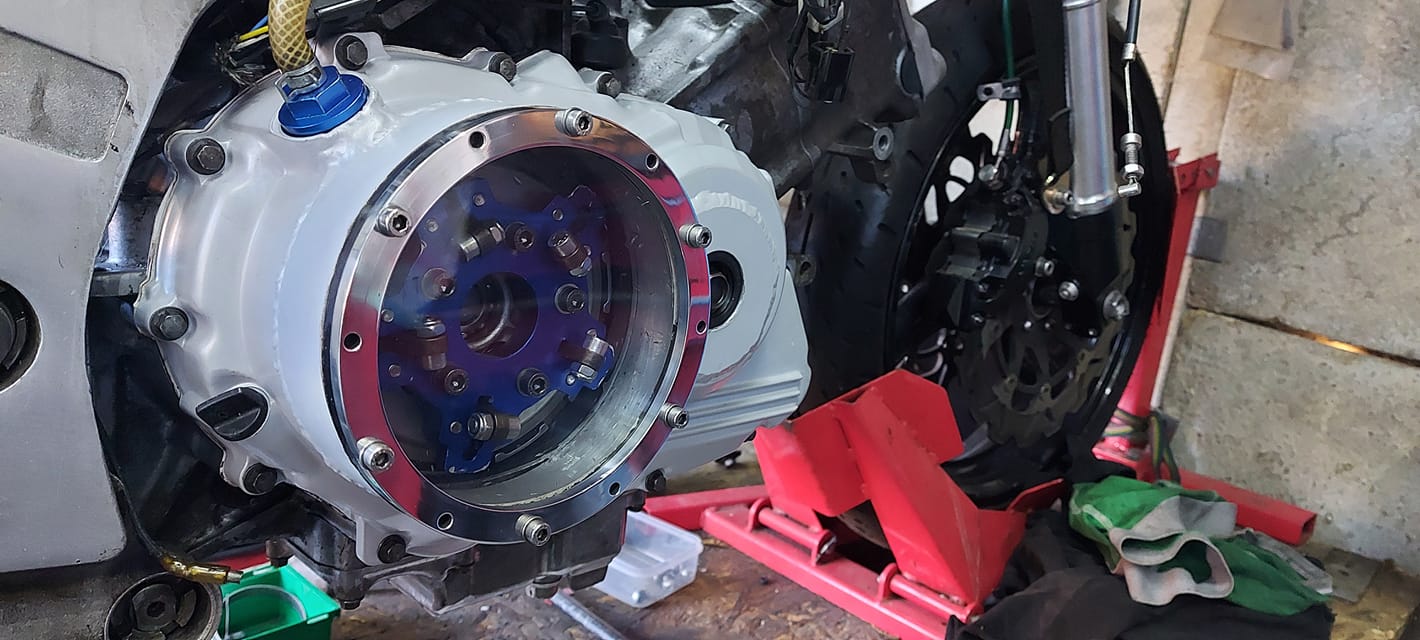

Shiny shiny

Aaaaaand I refitted the newly powder coated clutch casing today as well. In light silver which shows up nice in the sunlight, this service was applied by James at Superfinishingsuk (who will soon be opening a new premises near Dorchester in Dorset, all the best with that my man). I then complimented that by polishing the outer ring… to make it nice and shiny. I do have to redesign the gasket though as it shouldn’t be visible. Still, one step closer to getting it all back together.

-

Help, I’m bleeding…

After stripping the engine out last August, I later saw the fluid level in the clutch master cylinder had dropped. On inspection, the clutch slave cylinder seal had gone for the second time so decided to replace the whole unit. This Oberon piece landed on my doorstep recently and as the (rebuilt) engine is back in the frame, I was excited to fit it. It took 2 minutes to fit and bleed. The easiest bleeder I’ve ever done. Anyways, it all seems to work and it wasn’t expensive compared to an original Honda unit so here’s hoping it gives a better feel at the lever when it’s time to get…

-

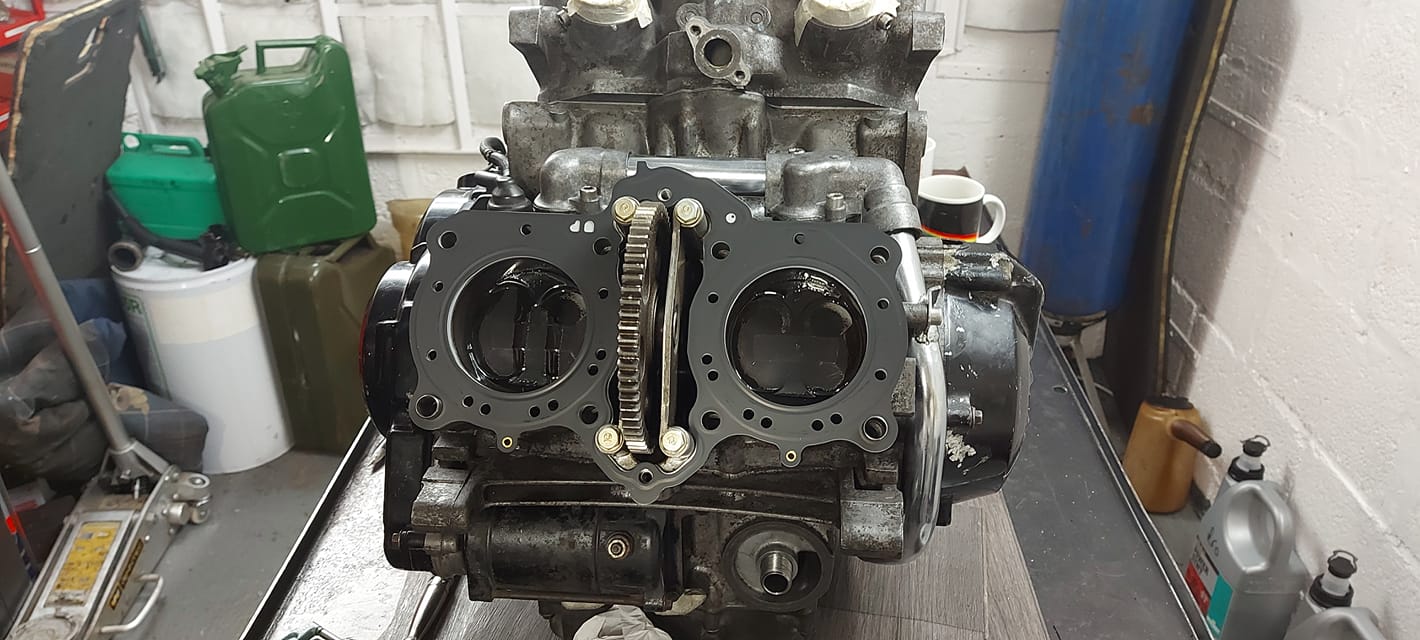

Shimming when you’re winning

So, a large part of today was spent fitting both heads and shimming the valve gaps. As I had lapped all the valves previously, it meant that most of the shims had to be replaced. Luckily, with shims from spare heads available, we were able to complete the task. Now to get it back in the frame…

-

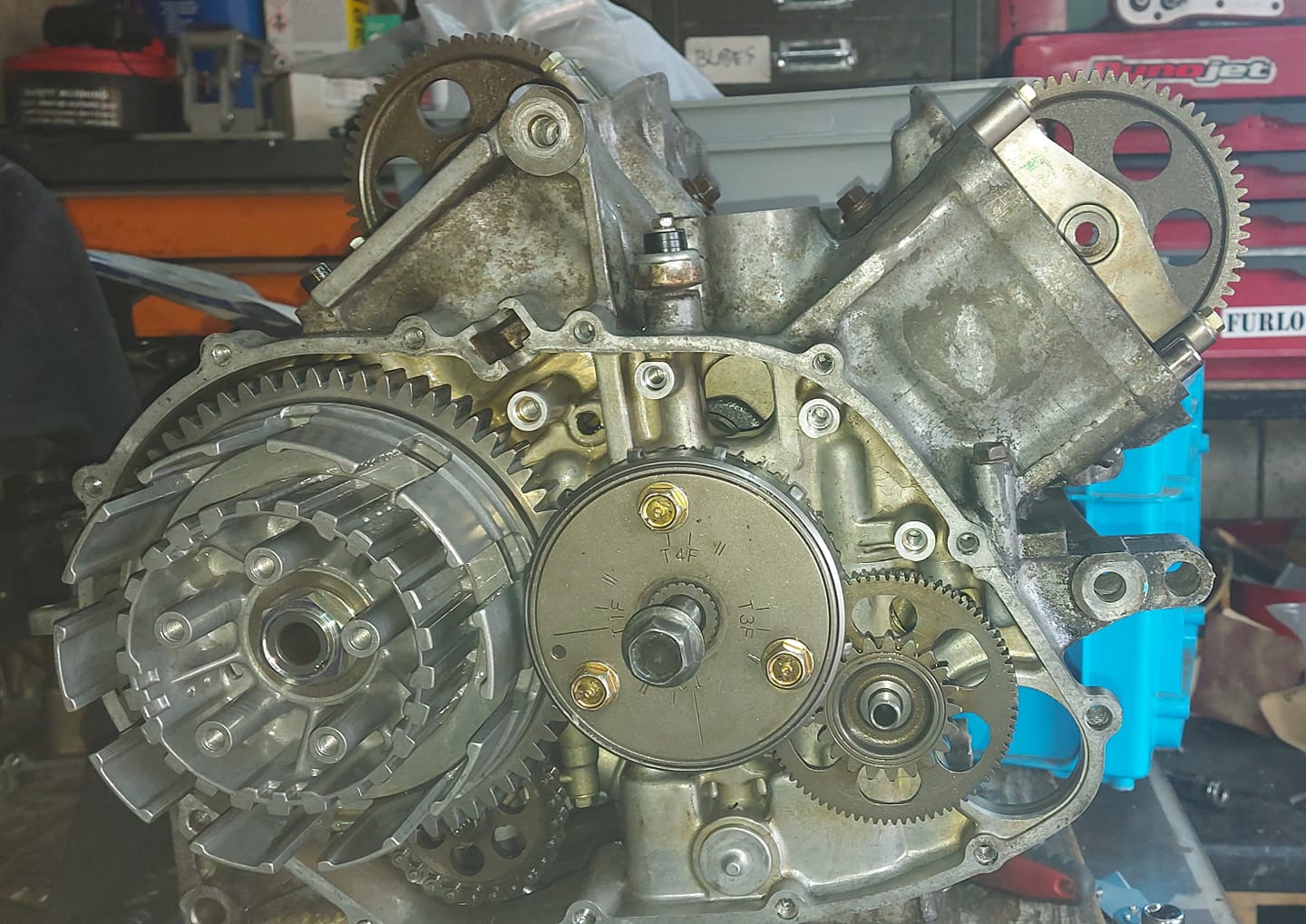

Gearbox – check!

The new superfinished and modified gearbox is in, the selector mechanism fitted and tis all working. Now refitting everything on the clutch side. The clutch basket has been rebuilt and polished by James at Superfinishingsuk in Bridport and is looking rather sweet. Next, the heads will be rebuilt and hopefully by the end of next week, the engine will be back together and replaced into the chassis (pronounced ‘shassee’ just in case you dint know ). We hope to try out a previously untried (by us or anyone we know of) tuning method which atm is top secret but should let us free the beast in our Mission 9 quest.

-

Prepping for rebuild

A fair bit of time yesterday was spent prepping the Ducks original engine ready for rebuild(draining of fluids, cleaning and removing old gasket material). Today, I went to advance to removing everything that didn’t need to be on there (heads and such like) only to find cylinder no 4 has a severe wear groove in the cylinder wall. I now have two choices. Get a new liner fitted which means crank and pistons out which is something we wanted to avoid or start the procedure all over again with another engine. The next engine is on the bench waiting for me to finish my (very much needed) cup of tea.…